"Production: where idea meets reality and innovation is born from determination."

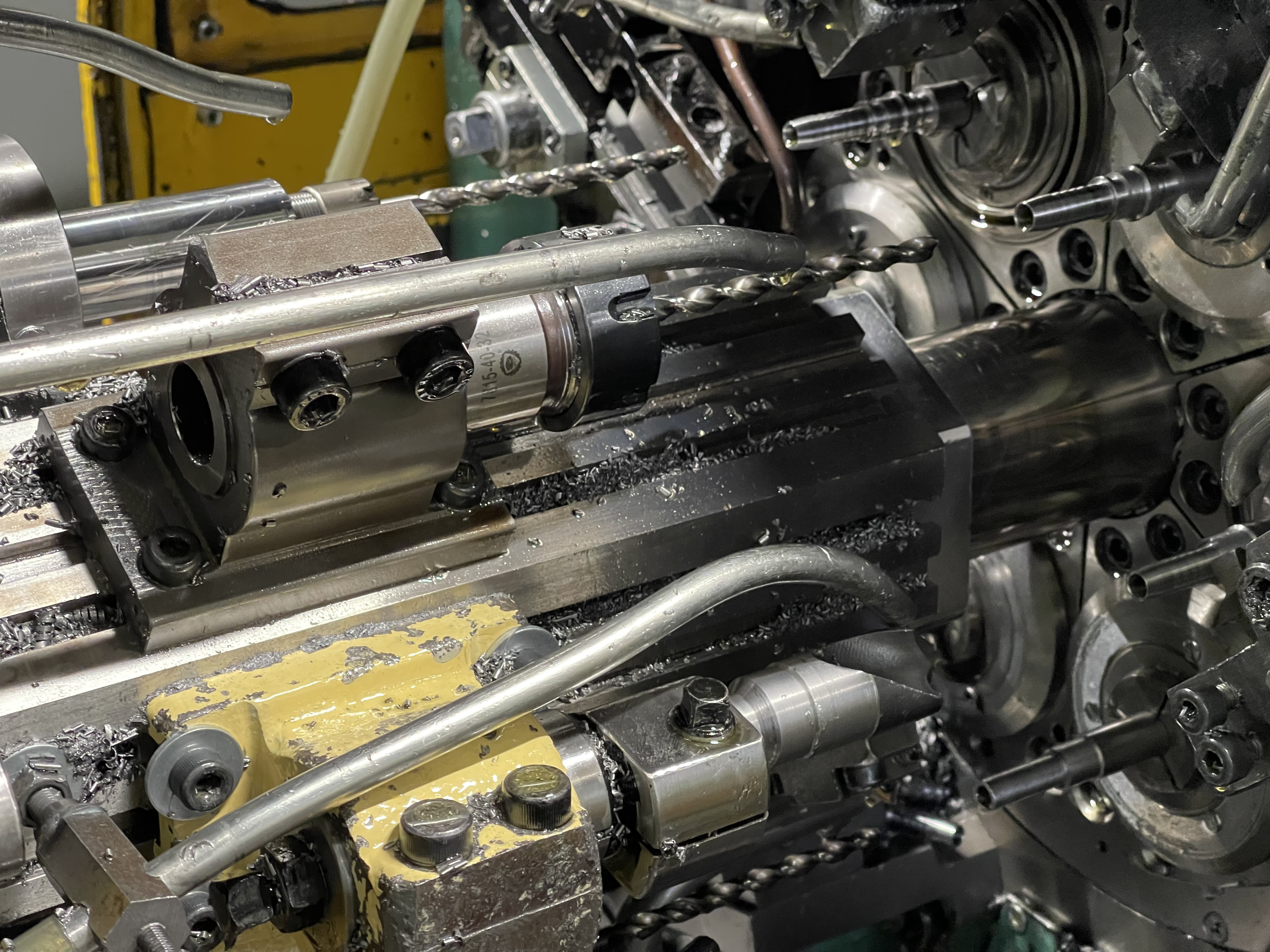

Turning medium and large series on multispindle automatic lathes of various types. We produce hydraulic fittings from bars from Ø10 to Ø67.

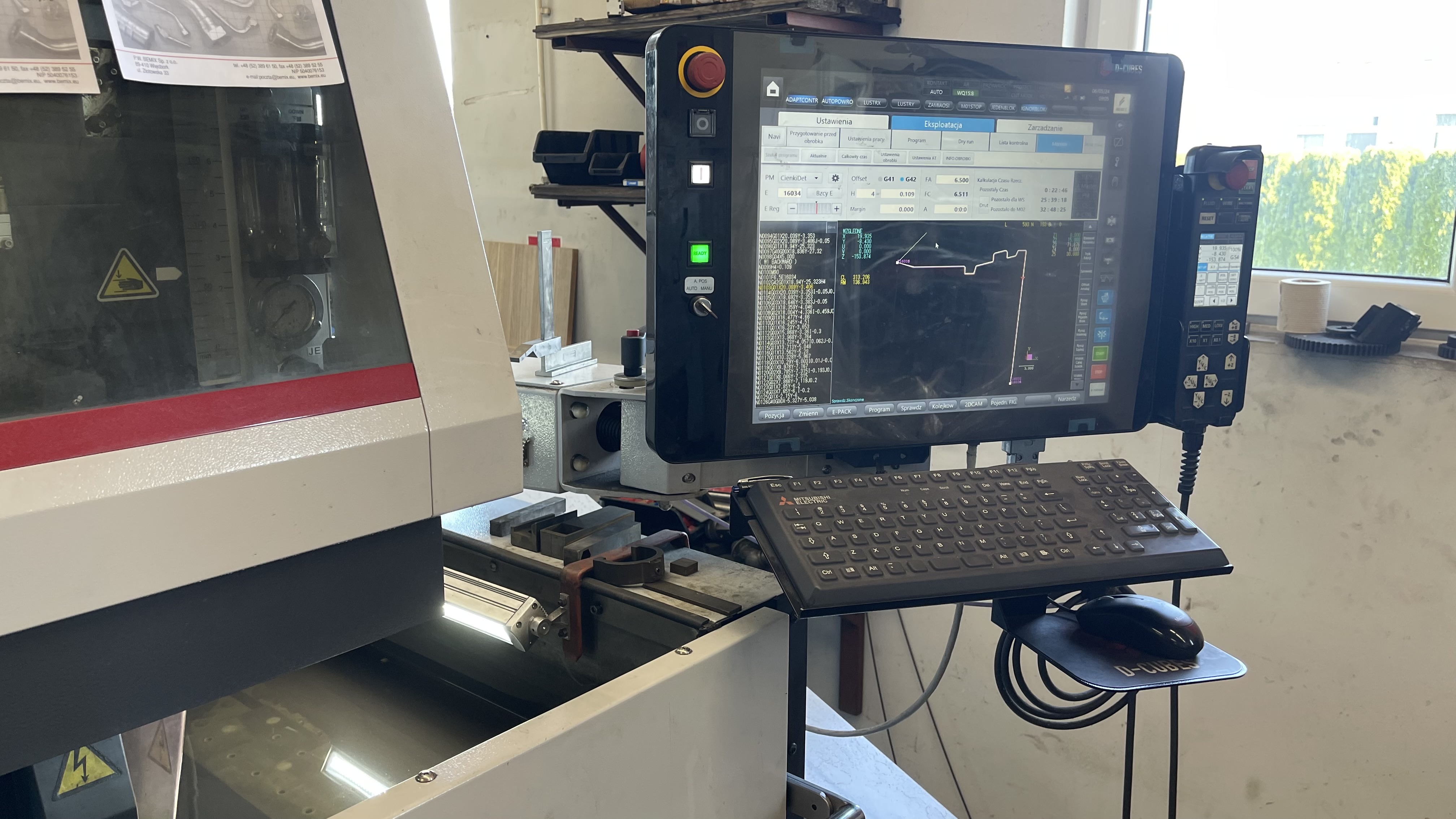

Turning of small and medium-sized series of hydraulic fittings. The maximum material processed is Ø82. Programming supported by the CAM system.

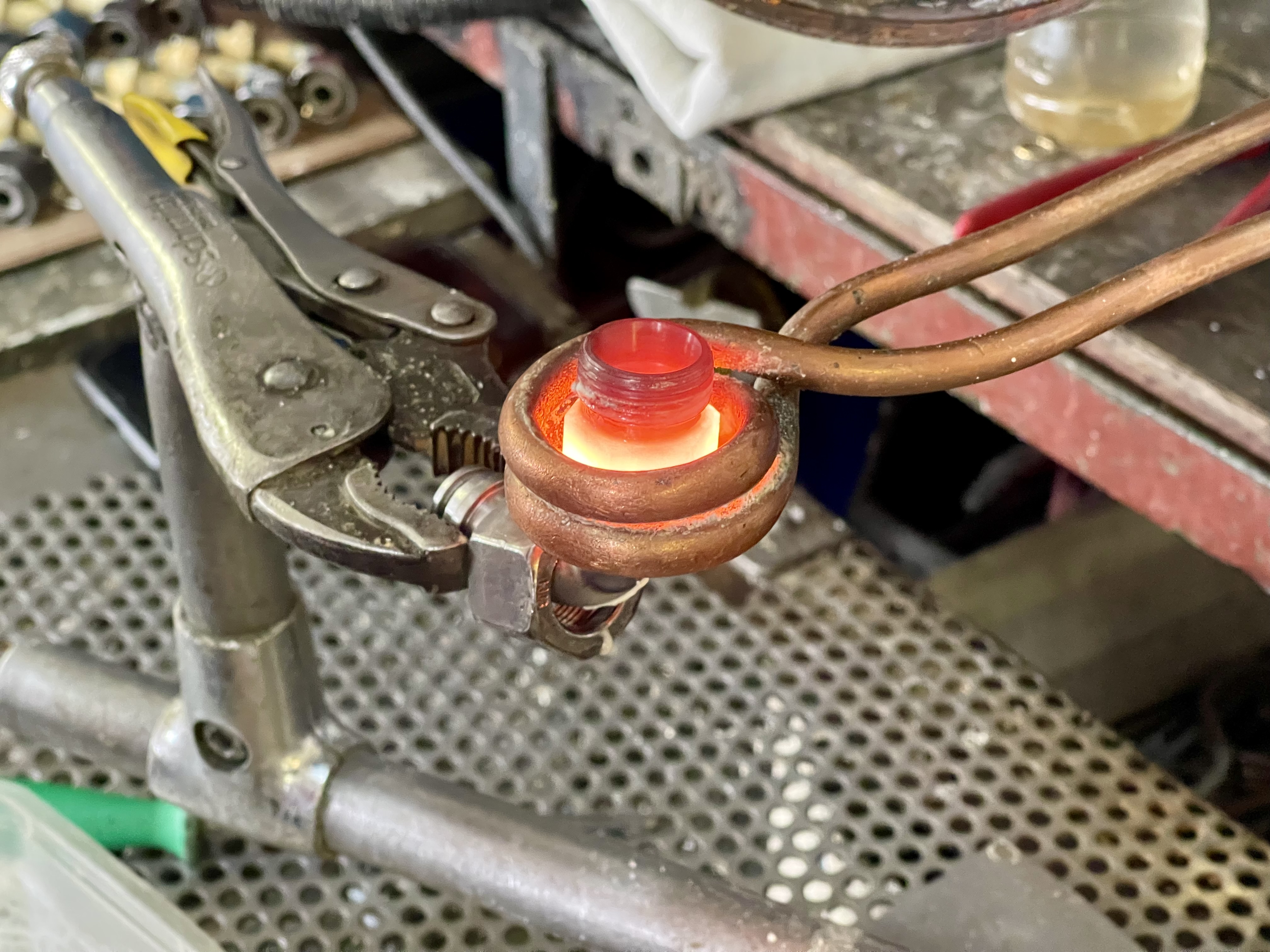

Soft annealing of ferrules and bending parts, as well as brazing, takes place in two tunnel furnaces in a protective atmosphere. We solder small batches using an induction generator.

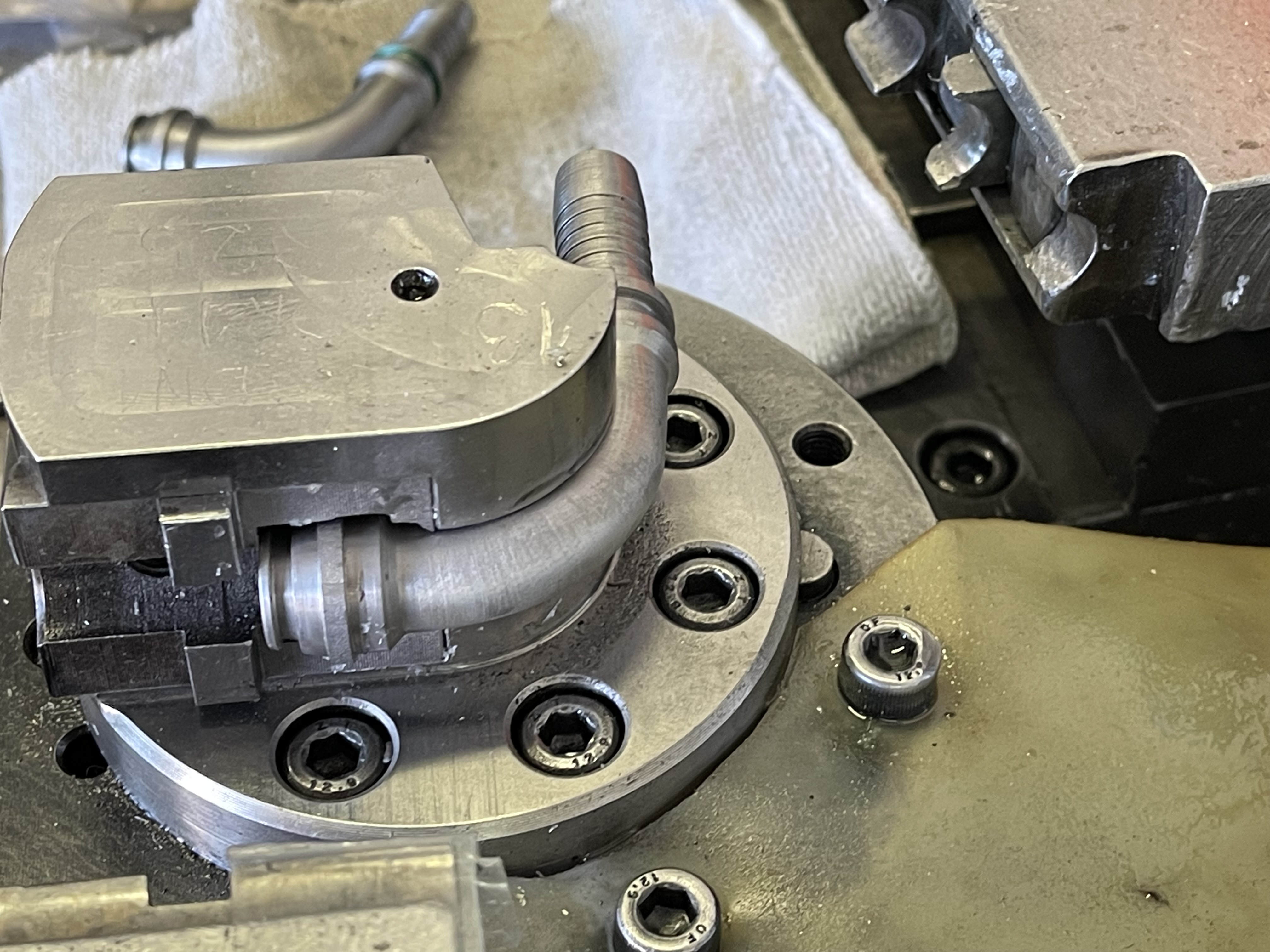

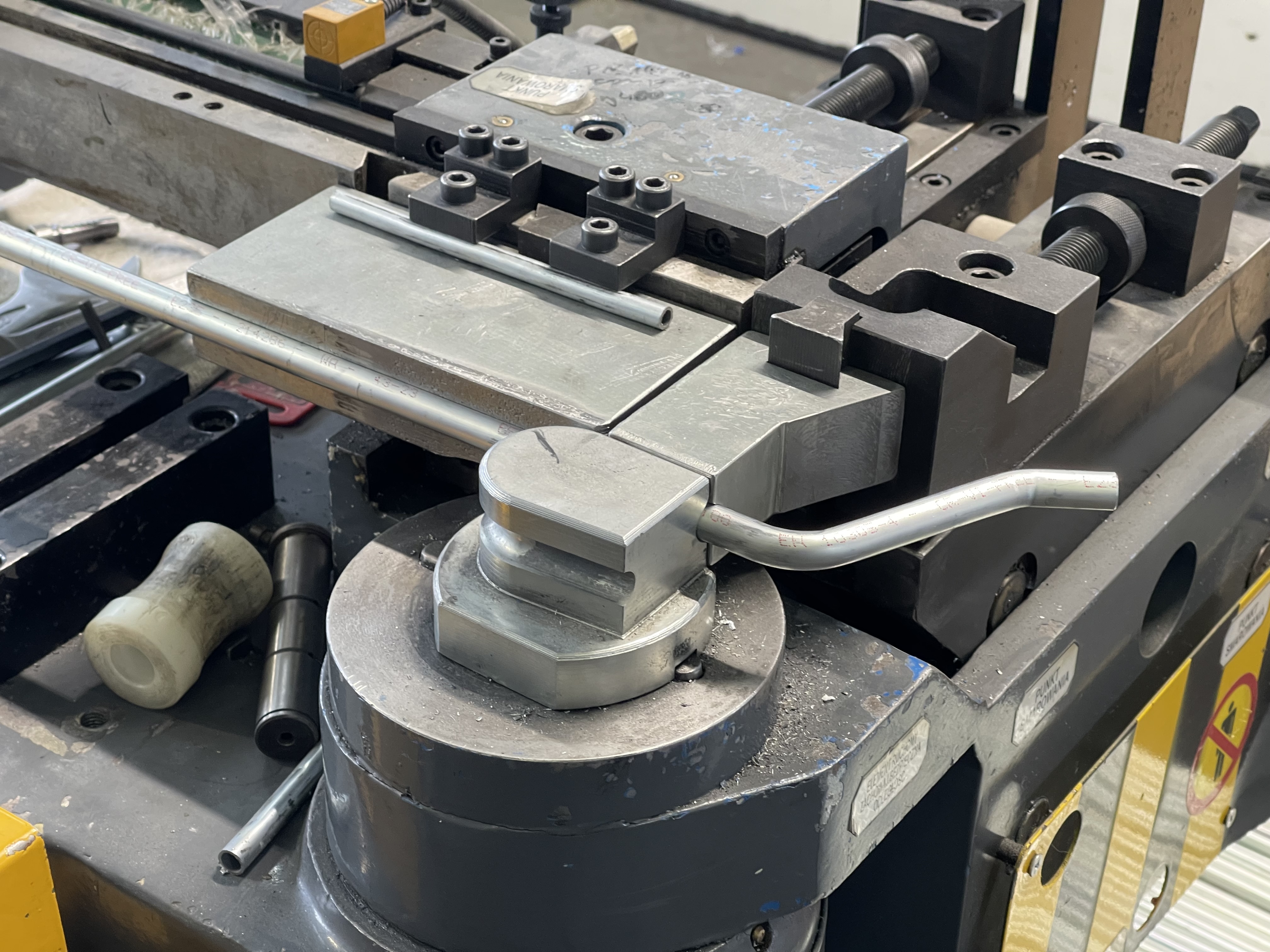

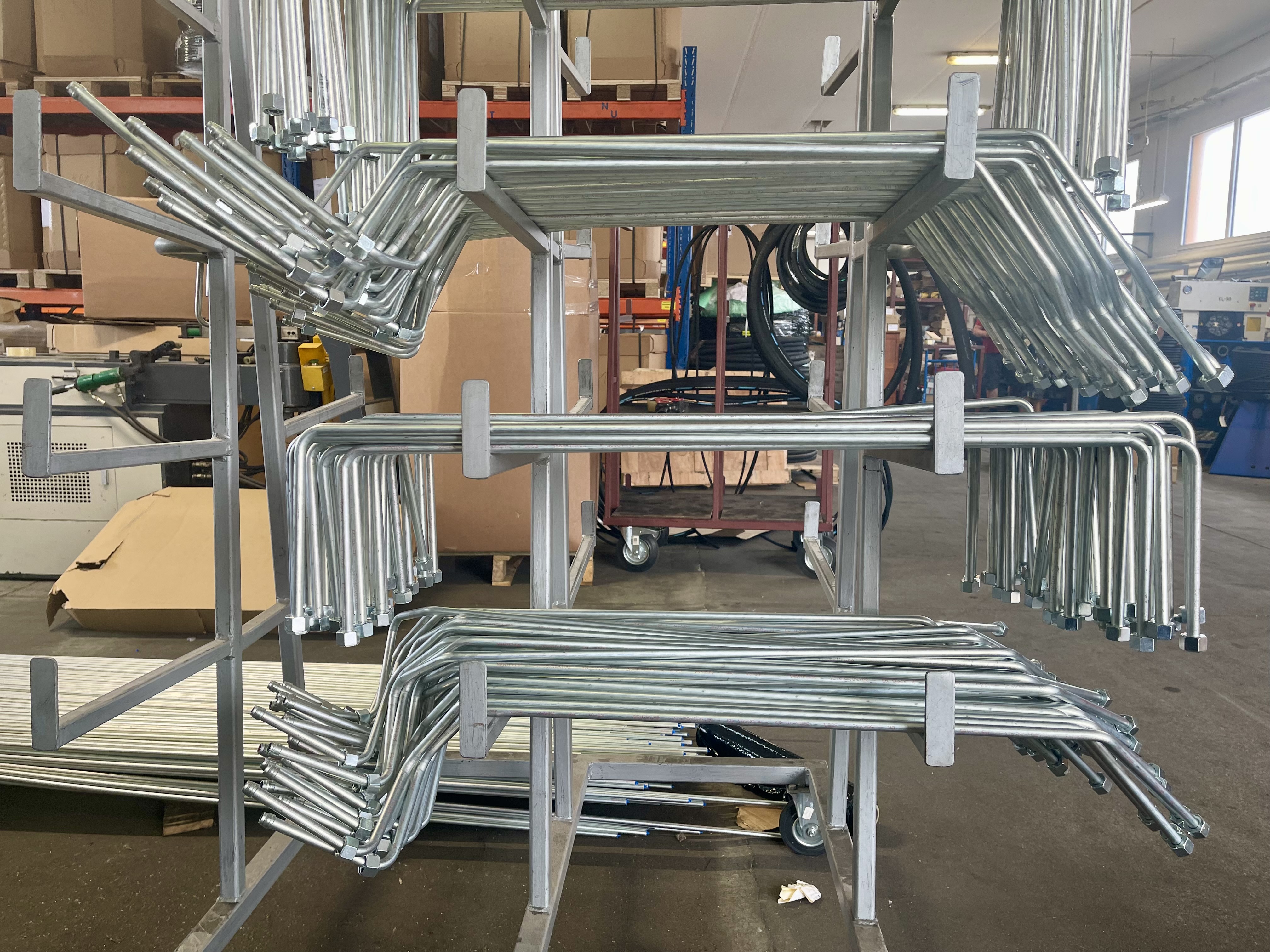

Bending of details at various angles is carried out on nine semi-automatic mandrel bending machines ranging from DN05 (3/16”) to DN50 (2”). Two CNC bending machines make pipe bending in 3D. On the bodies, we crimp the nuts from a hexagon S14mm to S75mm.

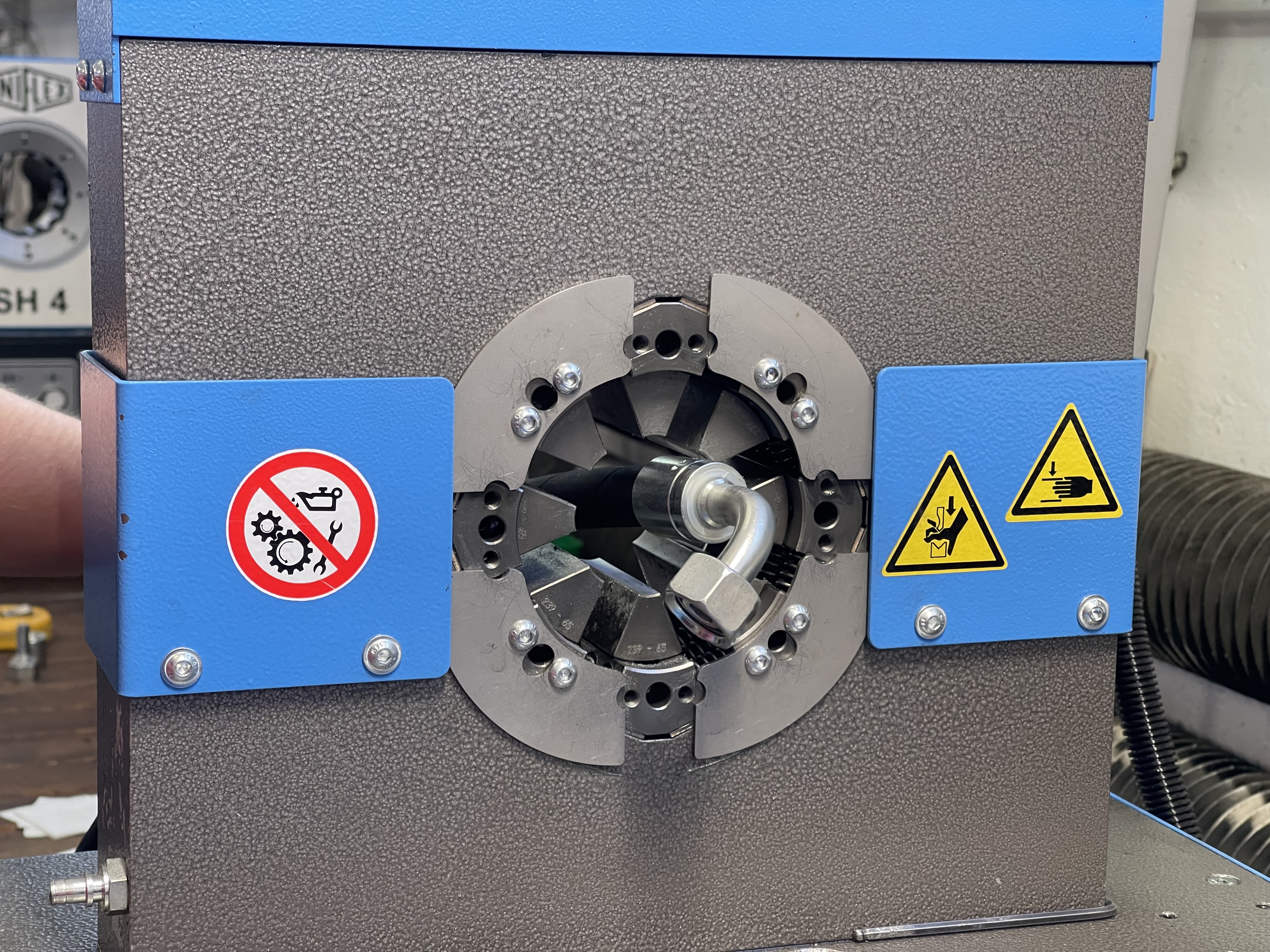

The line of hydraulic presses includes crimping machines for the production of large series of hoses and service crimping machines for hoses up to DN50 (2") 4SH Interlock. The equipment also includes automatic hose cutters and a station for testing the tightness of crimped pipes.

A modern fleet of specialized tool machines allows us to produce: shaped cutting tools, regeneration of used ones and making tooling for machine tools, which significantly shortens the time needed to start production from order.

English (United Kingdom)

English (United Kingdom)  Polski (PL)

Polski (PL)