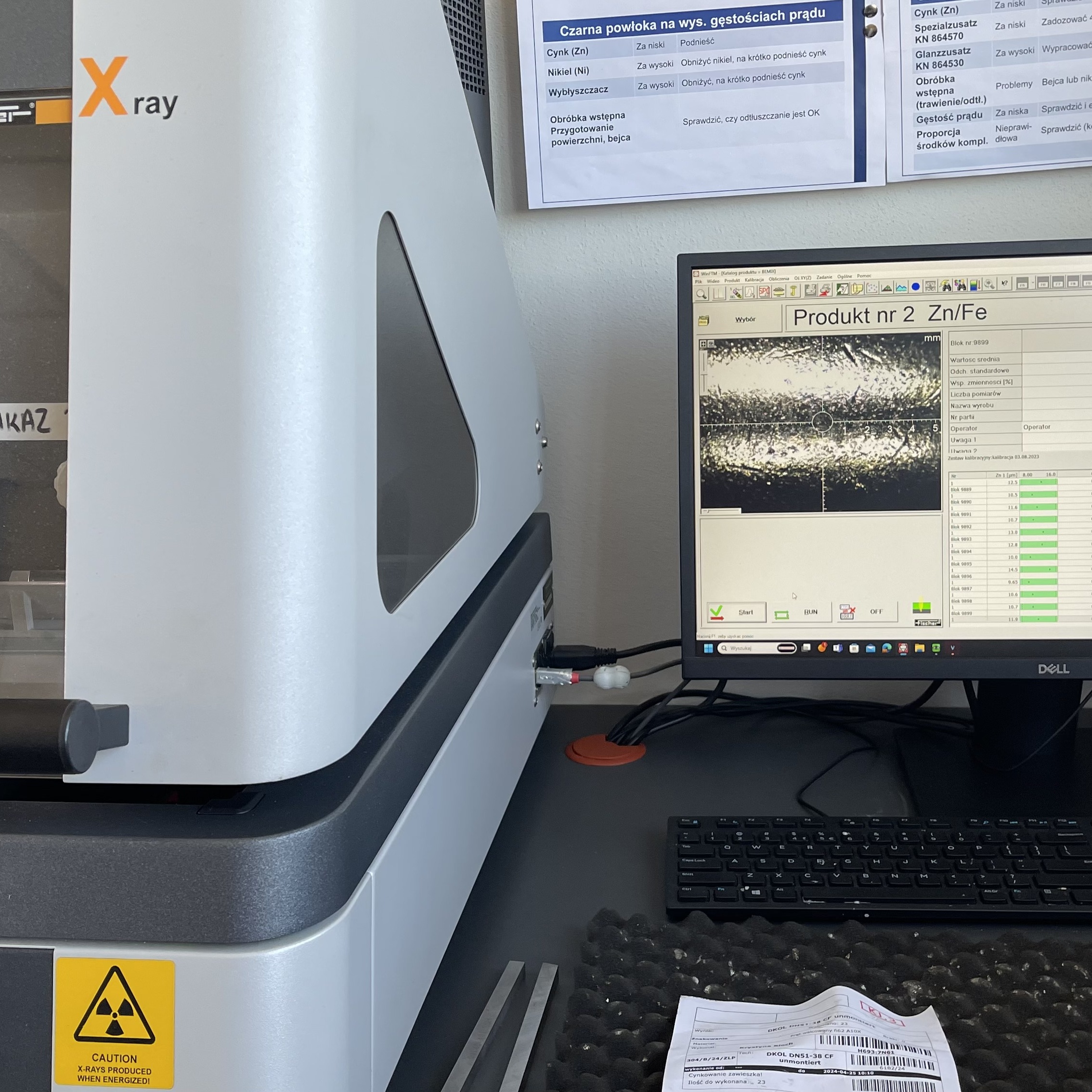

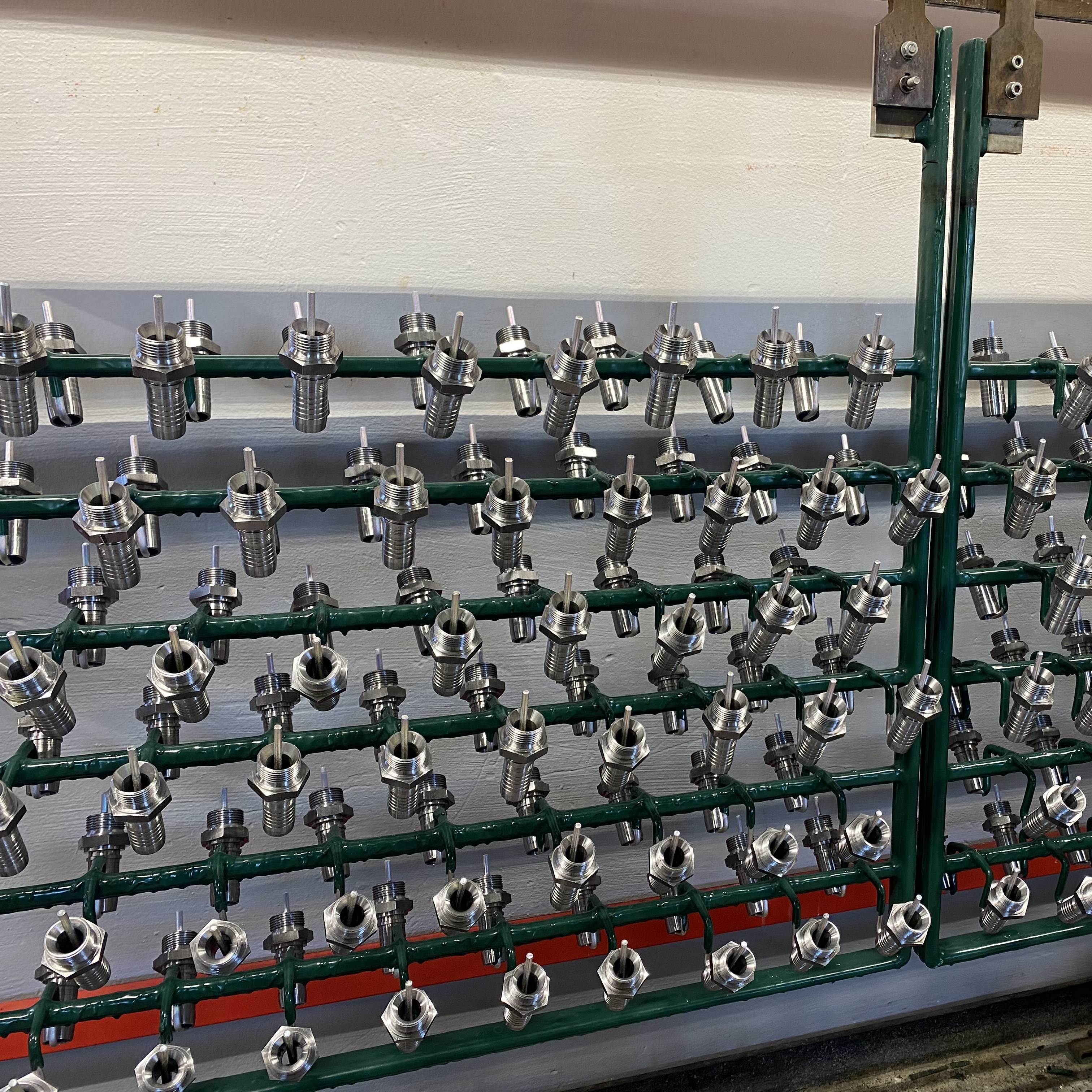

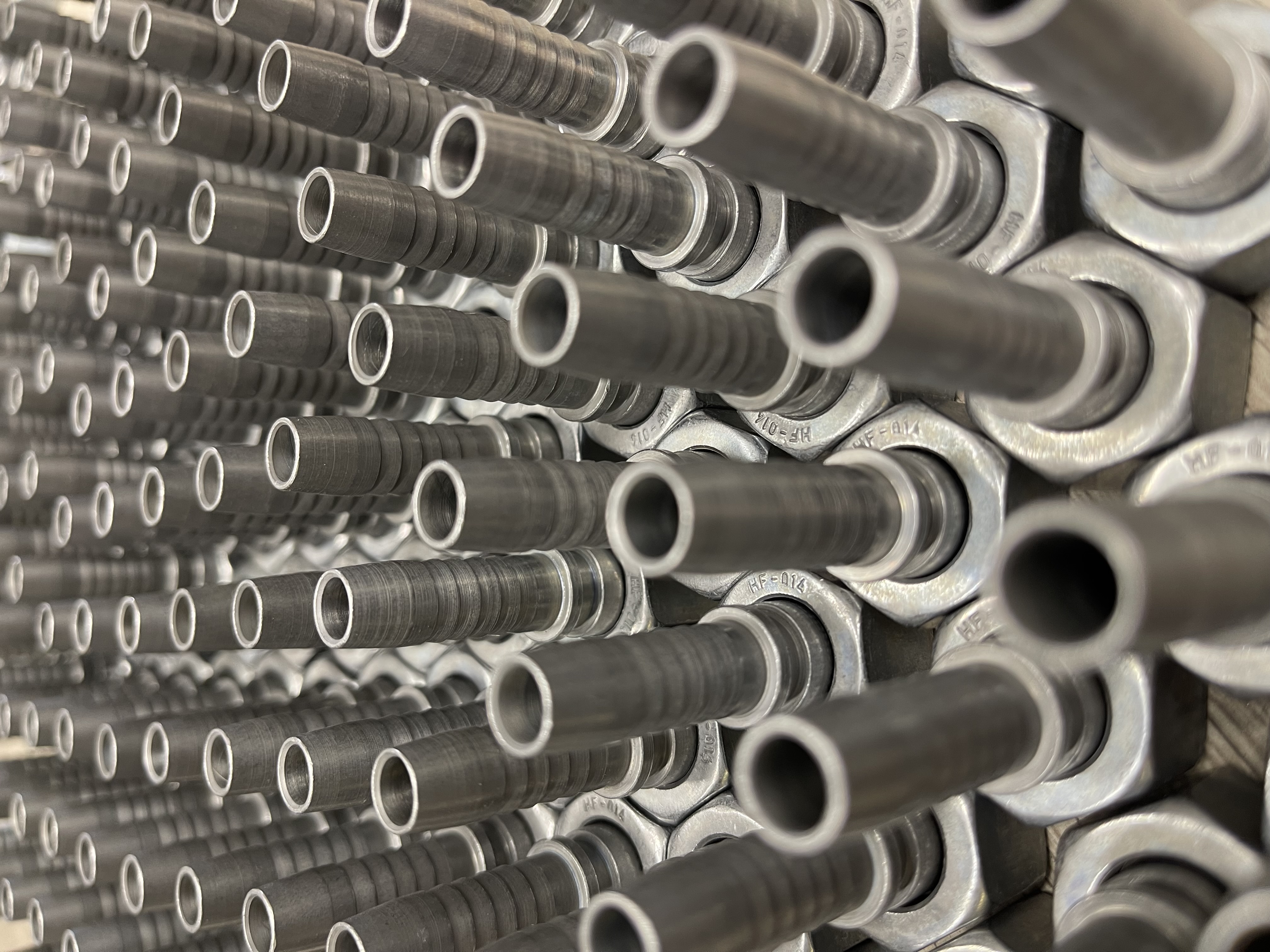

production- galvanic coating

"Proper protection is the key to excellence."

Alkaline zinc – Fe/Zn8/An/T2

- Electrolytic protective coating ZN alkaline,

- Transparent chromate passivation free from Chromium (VI),

- Corrosion resistance is a minimum of 72 hours to red corrosion in a salt chamber,

- In order to better protect against corrosion and increase resistance at higher temperatures, we protect all coatings with a sealant (varnish).

Zink-Nickel – (Fe/ZnNi8/Cn/T2)

Alkaline alloy coating with additional sealant.

- Very high corrosion resistance (up to 1200 hours to red corrosion in a salt chamber),

- Details covered with this coating do not create corrosion cells when combined with aluminum,

- High corrosion resistance to temperature changes or operation at elevated temperatures,

- Lower emission of zinc compounds into the environment during use of products with this coating,

- Increased hardness compared to pure zinc coatings and other zinc alloy coatings, ensuring significantly increased resistance to mechanical damage.

Polski (PL)

Polski (PL)  English (United Kingdom)

English (United Kingdom)